A Managed, On-Demand Manufacturing Model for the Manufacturing Industry

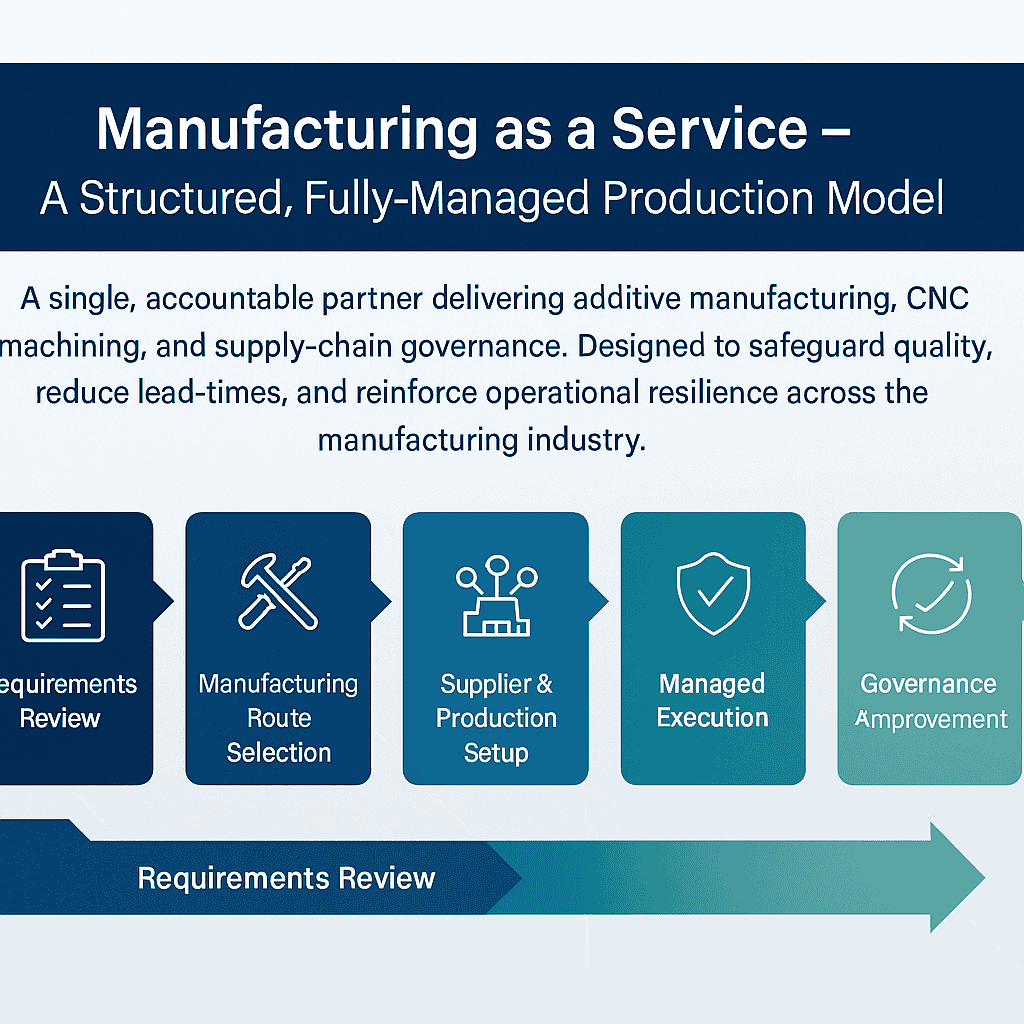

At Angus Solutions Ltd we recognise some companies don’t have the resources or the experience to manage the manufacturing process. We created our Manufacturing as a Service (MaaS) – managed network of additive + traditional suppliers, governed by Angus Solutions.

Manufacturing as a Service (MaaS) allows organisations to access high-quality manufacturing capability without owning or managing internal production assets. Instead of investing in machinery, tooling and specialist resources, you partner with us to oversee your full manufacturing lifecycle — from design support through to delivery.

This model gives you flexibility, resilience, and governance across both additive and traditional machining routes, delivered through a single accountable partner.

What MaaS Means for Your Business

Modern supply chains face pressure: fluctuating demand, extended lead-times, rising costs, and the constant need for technical capability. MaaS addresses these challenges through a professionally governed, on-demand manufacturing framework.

Our approach provides:

-

Scalable production capacity without capital expenditure

-

A curated manufacturing network covering additive, machining and composites

-

Governance, supplier oversight and strategic quality assurance

-

Reduced lead-times and improved delivery performance

-

A single partner responsible for outcomes, cost, and continuity

This is a strategic evolution of outsourcing — with accountability, control and manufacturing leadership at the core.

Our MaaS Delivery Framework

1. Assessment & Strategy

We begin by evaluating your product requirements, volume profile, supply-chain constraints and risk position.

We identify the most suitable manufacturing pathways — additive, CNC, or a blended route — based on cost, lead-time and quality objectives.

2. Managed Production Network

We operate a trusted network of manufacturing partners across the UK and international markets.

We manage:

-

Quoting and cost-modelling

-

Design-for-manufacture guidance

-

Supplier selection and capacity planning

-

Production scheduling

-

Inspection, quality governance and documentation

-

Consolidated dispatch and logistics

You gain the capability of a broad manufacturing estate, without the overheads of owning it.

3. Continuous Governance & Improvement

Our role extends beyond production. We provide ongoing oversight to ensure performance remains on specification and on schedule.

This includes:

-

Supplier performance monitoring

-

Lead-time and cost optimisation

-

Non-conformance management

-

Risk reviews and process improvement

-

Consultancy-led recommendations for future efficiency

This governance is what elevates MaaS from simple outsourcing to a fully managed manufacturing solution.

Benefits of Manufacturing as a Service

Reduced Lead-Times

By leveraging pre-qualified capacity and governed workflows, products move through production quickly and reliably.

Lower Capital Investment

You gain advanced manufacturing capability without machinery investment, maintenance burden or facility overheads.

Scalable Capacity

Production can be increased or decreased as market conditions change, with no disruption to internal operations.

Improved Supply-Chain Resilience

Centralised oversight reduces quality issues, supplier failures and continuity risks.

Access to Advanced Technologies

From metal additive manufacturing to multi-axis CNC machining, you benefit from a range of manufacturing technologies that would be impractical to develop internally.

Focus on Core Competencies

Your teams can focus on engineering, design, assembly and market growth while we manage the manufacturing burden.

Who MaaS Is Designed For

Our approach is especially suited to organisations requiring a dependable, governance-driven manufacturing partner:

-

OEMs and Tier-1/2 suppliers seeking assured capacity and reduced supply-chain risk

-

Product companies needing rapid prototyping through to batch production

-

Businesses launching new products requiring flexible early-stage volumes

-

Organisations rationalising supplier networks or in need of structured supply-chain oversight

-

Companies transitioning into additive manufacturing and requiring specialist guidance

How to Engage With Us

We recommend beginning with a structured Manufacturing Consultation.

This allows us to review your challenges, assess your current manufacturing posture and determine where MaaS can deliver measurable value.

Book Your 30-Minute Consultation

Begin the process of transforming your manufacturing capability through a professionally governed MaaS model.

Extensive Oil & Gas manufacturing experience.

We have many year experience in the manufacture and supply of components to the Oil & Gas industry and have established a network of manufacturing partners who also understand the manufacturing needs of this industry.

Specialising in the supply of Down Hole Tools

- Mechanical & Hydraulic Packers

- Flow Control Equipment:- Sliding Sleeves, Ball Valves etc

- Sand Screens :-Inflow Control Device (ICD), Autonomous Inflow Control Device (AICD)

- Safety Valves

- MWD Parts:- Measurement While Drilling

- LWD Parts :- Logging While Drilling

- Assembly & Testing

Offering

- CNC Turning

- CNC Turn-Mill

- 5-Axis Machining

- Honing

- Gun Drilling

- EDM

- CMM Inspection

- Induction Hardening

- Pressure Testing

- Coatings : – Zinc Phosphate, Baked Molykote, Xylan, Copper Plating.