A specialist service of Angus Solutions Ltd

Angus Solutions provides impartial, technically rigorous assessments and audits of subtractive & additive manufacturing companies to ensure they meet the process, quality, and material-control standards required for critical applications.

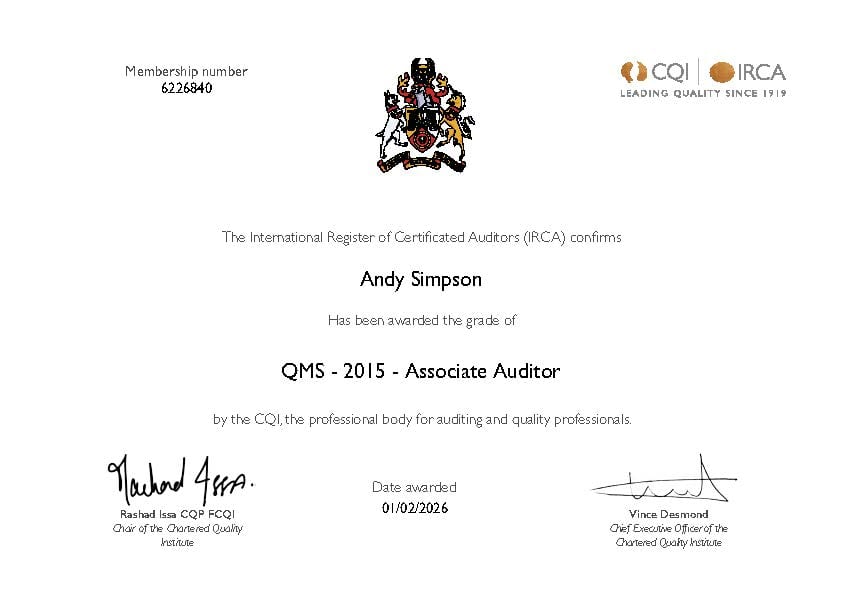

Audits are conducted by an ISO 9001 Lead Auditor, with a strong understanding of manufacturing environments and operational risk.

The approach is independent, structured, and commercially grounded, providing assurance leaders can rely on.

Our service is designed for OEMs, tier suppliers, and end-users who depend on reliable, qualified manufacturing partners and require confidence that their supply chain can consistently deliver compliant, high-integrity components.

ISO 9001 Auditing as a Service

Auditing is most effective when it provides leadership with objective insight into how a management system actually performs in practice—not just whether documentation exists.

Our ISO 9001 Auditing as a Service is designed to give organisations independent, evidence-based assurance over the effectiveness of their quality management system, with a strong focus on risk, control, and operational performance.

This service goes beyond compliance checking and supports better decision-making, improved system maturity, and sustained performance.

What the Service Provides

We deliver structured, professional audits aligned to ISO 9001 principles and best practice, focusing on:

-

System effectiveness – whether processes deliver intended outcomes

-

Risk and control – how well risks are identified, controlled, and monitored

-

Operational consistency – alignment between documented systems and actual practice

-

Leadership oversight – meaningful inputs for management review and decision-making

Audits are conducted using a risk-based, process-focused approach, tailored to the organisation’s size, complexity, and operating context.

Types of Audits Offered

The service can be delivered across a range of audit types, including:

-

Internal (First-Party) Audits

Independent internal audits to assess system effectiveness, identify improvement opportunities, and strengthen process ownership. -

Supplier / Second-Party Audits

Targeted audits of suppliers and subcontractors to provide assurance over capability, process control, and delivery risk. -

Readiness / Pre-Certification Audits

Objective assessment of system maturity prior to certification or recertification, identifying gaps before external scrutiny. -

Independent / Third-Party-Style Audits

Unbiased, certification-style audits providing leadership with an external perspective on system performance and risk exposure.

How the Audits Are Delivered

Each audit is planned and executed to ensure clarity, value, and practical outcomes:

-

Defined audit scope and objectives aligned to business priorities

-

On-site and/or remote audit activity as appropriate

-

Evidence-based findings, focused on effectiveness rather than paperwork

-

Clear, prioritised outputs highlighting risk, gaps, and opportunities

-

Professional reporting suitable for leadership and management review

The emphasis is always on useful insight and actionable improvement, not generic audit reports.

Who This Service Is For

This service is particularly valuable for organisations that are:

-

Scaling operations or supply chains

-

Preparing for ISO 9001 certification or surveillance audits

-

Seeking stronger assurance over internal processes or suppliers

-

Wanting to extract real value from their audit programme

Professional Assurance

Audits are conducted by an ISO 9001 Lead Auditor, with a strong understanding of manufacturing environments and operational risk.

The approach is independent, structured, and commercially grounded, providing assurance leaders can rely on.

Independent Capability & Compliance Assessments

We evaluate AM suppliers & Companies against recognised standards and best-practice frameworks, including:

- ISO 9001:2015 – Quality management systems

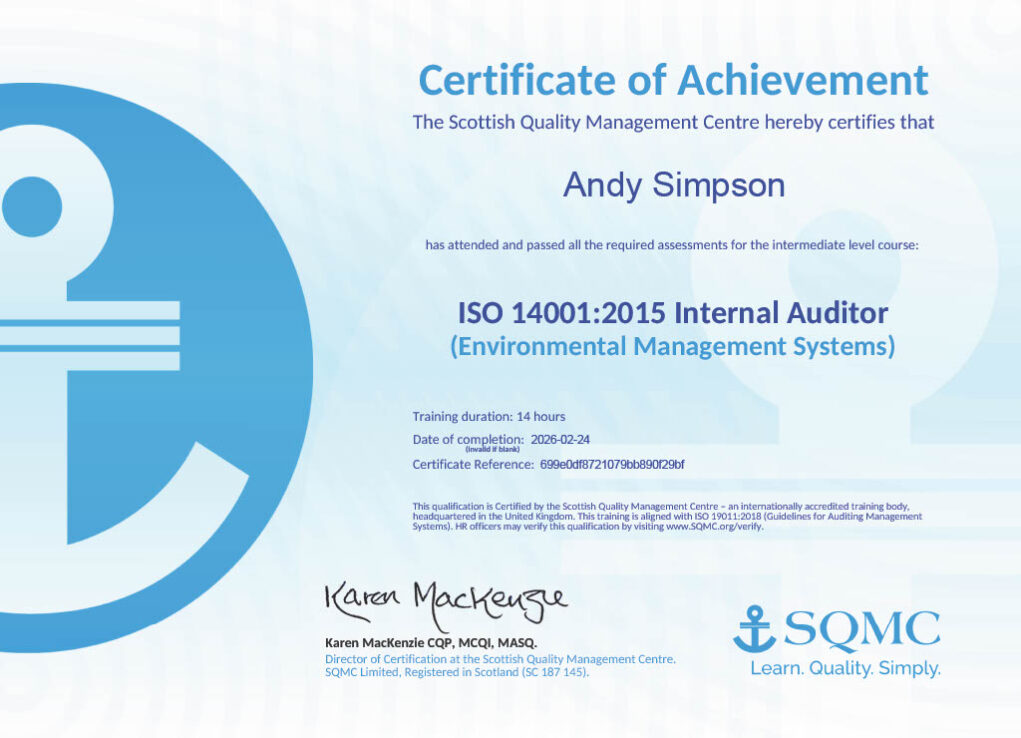

- ISO 14001:2015 – Environmental management systems

- ISO 45001:2018 – Occupational health and safety management systems

- ISO/ASTM 52901 – Additive Manufacturing: General Principles

- ISO/ASTM 52920 – Qualification of Machine Operators

- ISO/ASTM 52930 – Qualification of AM Service Providers

- Industry specifications – API 20S, DNV-ST-B203